We validate cleaning procedures to meet regulatory requirements, ensuring consistent and uniform results. To ensure this we follow industry practices that have been proven to be robust for cleaning validation, however we can tailor this to suit your unique requirements.

Ultimately, the success of any validation process depends on scientific data showing that the system or process consistently performs as expected and produces results that meet predetermined criteria. We have expertise to assist you in achieving consistent and repeatable results of your cleaning process.

Quality in all that we do…

Clean-In-Place (CIP)

Steam-In-Place (SIP)

We validate steam-in-place processes (sometimes known as Sterilisation-in-Place) in compliance with regulatory requirements. These processes are crucial for equipment that cannot be autoclaved, ensuring consistent and reliable log reduction of bio-burden. Our approach involves utilising thermometric data and, when necessary, biological indicators to achieve consistent and robust log reduction results of the bio-burden (6-log for sterilisation). With our expertise, you can achieve reliable and repeatable results for your steam-in-place processes, backed by scientific data that meets pre-determined criteria.

Computer System Validation (CSV)

We have the expertise and experience to fully validate your computer system hardware and software in line with regulatory requirements and your validation master plan.

As with all of our validation packages, we can validate your systems from the design stage if needed, before conducting IQ, OQ, PQ and development testing.

Operational Qualification includes testing under both normal and worst-case conditions to ensure the critical inputs and outputs are as expected.

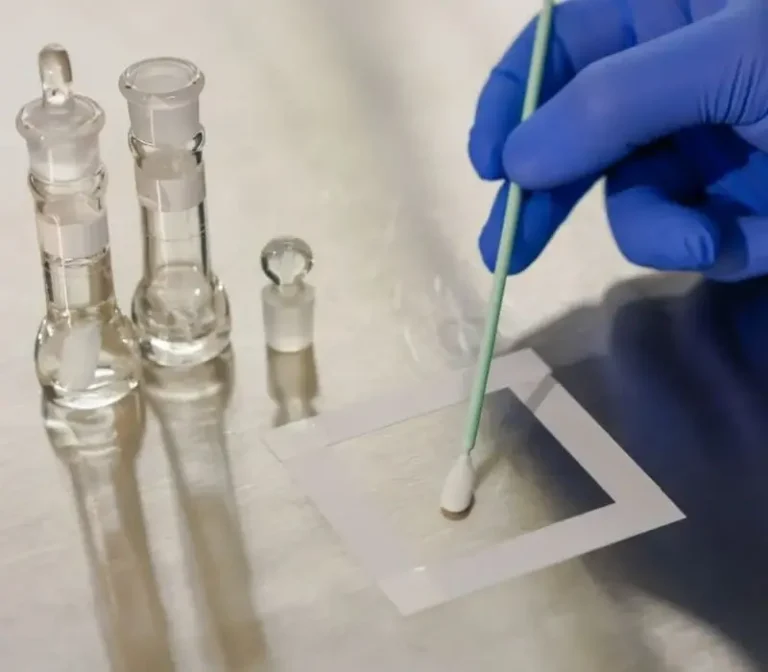

Cleaning Validation

We validate cleaning procedures to meet regulatory requirements, ensuring consistent, uniform and repeatable results. To ensure this, we follow industry practices that have been proven to be robust for cleaning validation, however we can tailor this to suit your unique requirements.

Process Validation

We have experts who can assist with the four main stages of process validation: Process Design, Process Qualification (which involves qualifying the design of the facility and the equipment/utilities within it), Process Performance Qualification (which confirms if the commercial manufacturing process performs as expected) and Continued Process Verification. Due to the team nature of process validation, we will work to provide the right person that meets your team’s required skill set.