In the world of validation, managers often find themselves facing a critical choice: “Would it be better to manage validation activities internally or to outsource them to external partners?” This decision is far from straightforward, as it entails multiple considerations. This article aims to provide validation managers with a balanced and informative guide to help make an informed choice that aligns with their organisation’s unique needs.

There are several advantages to outsourcing validation that one must consider:

- Access to Specialised Expertise: Outsourcing validation activities provides access to specialised knowledge and technologies that may not be readily available in-house. Although it is possible to recruit people with domain knowledge or even develop this in-house, external experts can bring specific expertise of validating a particular process or piece of equipment across a greater range of life science companies, often leading to fresh perspectives to validation problems and harmonisation with best industry practice.

- Flexibility and Scalability: Outsourcing offers the flexibility to scale up or down quickly and as needed. This can be especially advantageous when facing fluctuating workloads or short-term projects. This can lead to greater cost efficiency in the long term as service providers usually need only be paid for the fixed agreement or duration of the project.

- Time Efficiency & Savings: Currently, timescales to complete projects are getting shorter and outsourcing can be the solution to meet tighter deadlines. Service providers and contractors aren’t usually limited to working a 9 to 5 standard working day, often working longer hours than permanent staff to meet project deadlines. It is worth considering the financial cost of validating the equipment vs the market value of bringing a product to market x number of weeks/ months faster.

- Compliance and Regulatory Expertise: External partners need to have an up-to-date understanding of the latest regulations and best industry practice, ensuring a high level of compliance.

- Test equipment: Whilst using a service provider, often the correct validation test equipment is supplied as part of utilising their engineers, this is particularly advantageous, as it negates the need to resource equipment of your own for short-term use, which is usually the case when using permanent staff or contract staff.

There are however some downsides to outsourcing, which are as follows:

- Perceived Higher Upfront Costs: Although outsourcing may initially appear more expensive due to higher hourly rates of general contractors, it can ultimately save costs through increased efficiency and reduced long-term expenses. The full cost impact needs a careful analysis after quotations have been obtained from providers. A holistic approach should be taken, considering the short-term and long-term costs for both insourcing and outsourcing approaches.

- Intellectual property posing communication and coordination challenges: Collaborating with external partners can involve more communication and alignment efforts compared to managing validations internally. Strong project governance and a good supplier relationship is essential to mitigate this risk.

- IP rights: During engagements, appropriate contractual terms should safeguard intellectual property shared with partners. Many companies require contractors and suppliers to sign non-disclosure agreements, preventing the sharing of sensitive information between competitors.

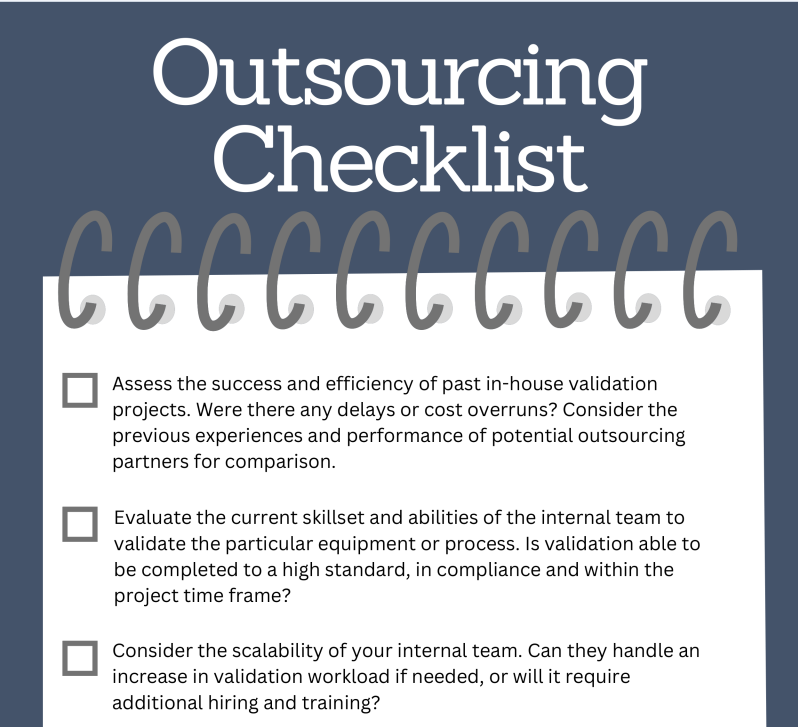

Unlock the potential of seamless decision-making with our free, interactive 11-point validation outsourcing checklist. Click here to download your free copy.

Conclusion

Ultimately, the decision whether to outsource should be taken on an individual basis, as each site’s project requirements, internal capabilities and budgets are unique. It is worth mentioning that outsourcing doesn’t have to be an all-or-nothing proposition. Many companies choose to have a hybrid model, keeping strategic validation activities in-house while outsourcing specialised, labour-intensive tasks. For example, one of our pharmaceutical clients chooses to do all their annual qualifications in-house but makes use of our expertise and flexibility to source and qualify new equipment. Our extensive experience within the industry allows us to properly address the URS and FS ahead of time, making sure the equipment is fit for purpose ahead of development and qualification, saving unnecessary costs on unsuitable equipment that does not meet the needs of the client. This approach balances their control with flexibility.

When deciding to outsource validation services, it’s crucial to evaluate potential validation partners based on their technical capabilities, experience, ability to mitigate risks, management practices, and cultural fit. Typically, there are three main ways to outsource validation: engaging a validation service provider, sourcing a contractor directly, or using a recruitment agency. These methods will be thoroughly evaluated in a future article, please subscribe to our ‘Validation Insights’ mailing list below to ensure you don’t miss out.