In the life science industry, proper sterilisation of medical devices, instruments, and equipment is paramount to the safety of patients. One critical aspect of steam sterilisation quality control is the Bowie and Dick test (also known as the Bowie Dick Test or an Air Removal test). As part of BS EN 285:2015+A1:2021, the Bowie and Dick test is a mandatory test for vacuum porous load steam sterilisers and forms part of routine monitoring and control steps outlined in BS EN17665 to maintain operational status. It is also recommended that the test be performed as part of the Operational Qualification (OQ) and Performance Qualification (PQ) during validation. Please, note the Bowie and Dick test is just one of nine suggested tests recommended for steam sterilisers during operational qualification.

Why is the Bowie-Dick test conducted?

To make sure vacuum porous load sterilisers are functioning properly, Bowie-Dick tests are used to check if air has been adequately removed from the chamber and that steam has successfully penetrated the test pack. Pockets of air left in the steriliser are problematic because they function as a barrier that prevents steam from penetrating the load, hindering the sterilisation process. Please note that the test does not confirm if sterilisation conditions have been achieved and is designed to complement the small load thermometric test. Both tests should meet their acceptance criteria before acceptable air removal and steam penetration are verified.

A failed test indicates the retention of air in the test pack which can be due to:

-

Ambient or high-pressure air leaks: Air can enter the chamber during the sterilisation cycle if there are leaks in the steriliser’s door gasket, valves, or piping.

- Inefficient air removal: Pre-vacuum sterilisers rely on a series of vacuum pulses to remove air from the chamber before introducing steam. If the air removal process is insufficient pockets of cooler air can remain, leading to uneven sterilisation.

- Non-condensable gasses (NCGs) in the steam supply: NCGs are air and/or other gasses that will not liquify under the conditions of saturated steam sterilisation processes. Sterilisers should be designed to operate with saturated steam containing up to 3.5ml non-condensable gasses/ 100ml of condensate when assessed using steam quality testing, however, more than this can cause the efficacy of the sterilisation process to deteriorate.

What is the history of Bowie and Dick testing?

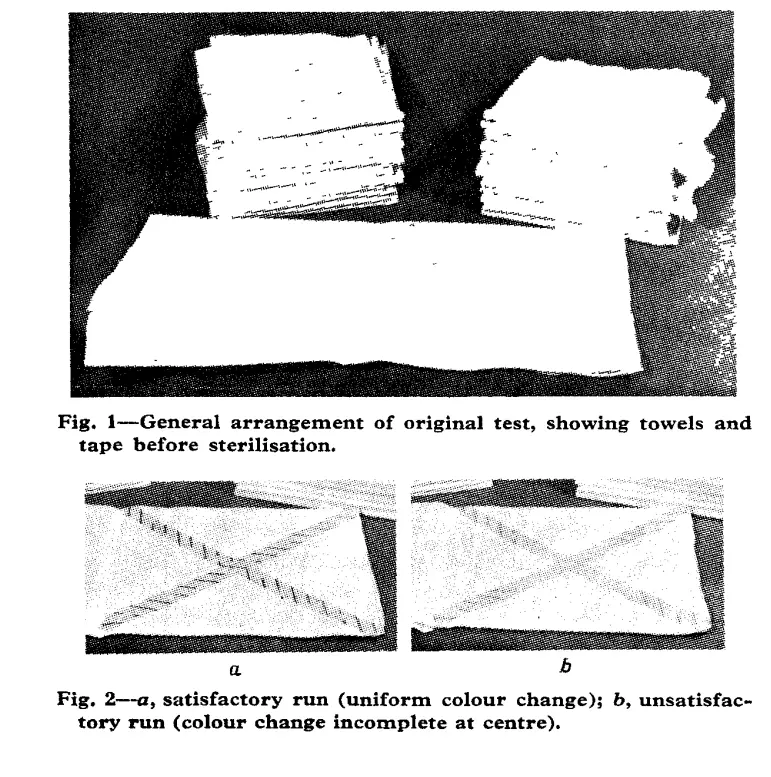

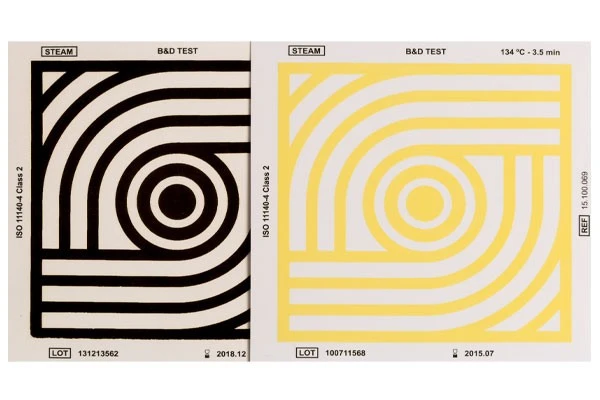

The test was first referenced in a 1963 Lancet journal article by members of the Working Party on Pressure Steam Sterilisers, established in 1957 to improve the safety of steam sterilisation. The test involved folding and stacking nineteen huckaback towels into a rectangular dressing casket. Two 12-inch lengths of autoclave tape “type 1222” were stuck to the towels in the shape of St Andrews cross and subjected to a sterilising cycle. If after one run there was a uniform colour change throughout the tape, then the test and steam penetration were considered successful. An incomplete colour change indicated an unsatisfactory run. Please note that even then, they noted the need to not interpret the results alone and to have a supporting record of satisfactory time-temperature relationship in the chamber drain.

When should the Bowie-Dick test be performed?

When dealing with medical devices and as per BS EN 17665 2024 it is recommended to perform the test at least daily. In some high-risk applications such as decontamination in hospitals, then the test is also performed quarterly and annually as part of revalidation tests (see HTM 2010).

How is the Bowie-Dick test completed? What does the Bowie-Dick test involve?

Apparatus needed:

- A standard test pack which meets the requirements set out in BS EN285 clause 23.1 for sterilisers with >1 sterilising module. For sterilisers with one sterilising module, a reduced test pack may be used, as outlined in clause 23.2.

- A class 2 chemical indicator, in accordance with EN ISO 11140-3, ISO 11140-4 and ISO 11140-5. These usually come on indicator paper or as part of[YW1] pre-made disposable test packs, however in the last 10 years, electronic Bowie-Dick tests have become available. If using these, then it should be demonstrated that the electronic Bowie-Dick test still meets the above requirements and shows equivalence to the standard test pack as originally outlined in EN285.

Process:

- Before running a Bowie-Dick test, it is important to run an operating cycle in the empty autoclave first, without any extended drying time. This will ensure that all parts of the autoclave are up to working temperature and dry, as this can affect air removal. Please note: this cycle may be omitted if data is available to demonstrate that conditioning by the previous cycle has a similar effect.

- Remove the wrapping from the test pack and place the indicator inside the centre.

- Reassemble the test pack per clause 23.1/ 23.2 of BS EN285.

- Place the test pack above the nominal geometric centre of the horizontal plane of the usable space supported between 100 mm and 200 mm above the steriliser chamber base. For sterilisers of only one sterilising module, the method is changed so that the test pack is supported above the base of the sterilising chamber. These recommendations are based on the BS EN285 however, it is[YW1] important to read the manufacturer’s instructions for the autoclave and check where the manufacturer recommends putting a Bowie-Dick test kit.

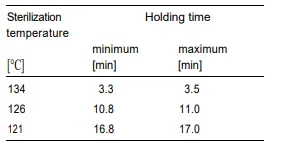

- Conduct an operating cycle or Bowie-Dick test cycle (if available). For this, it is important to ensure that the holding time does not exceed the times specified in the below table.

- Once the cycle is complete , the test pack needs to be removed from the steriliser, and you must wait for it to cool down before examining.

Result:

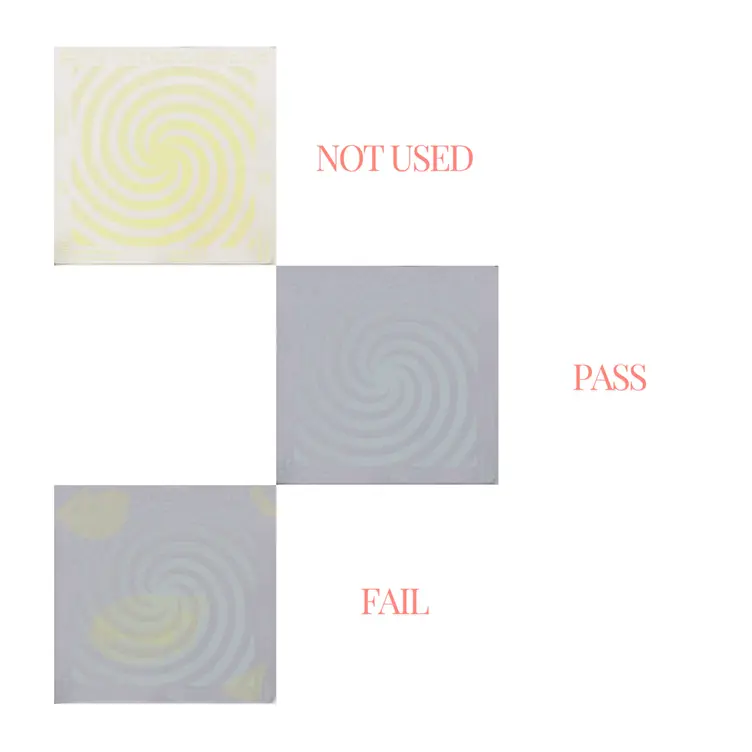

Compare the colour of the indicator paper at the corners compared to the middle.

- If satisfactory, the thermochromic paper inside the pack will change colour to indicate if steam has penetrated the porous load. During examination, one should look for a uniform colour change, across the indicator paper, indicating acceptable air removal.

- No change or partial colour change indicates an unsuccessful test cycle. If the Bowie-Dick test fails, further thermometric testing must be initiated to determine the underlying cause. Any pre-vacuum autoclave should not be used until the underlying cause is determined and the necessary corrective and/or preventative action is taken. The test should then be repeated with a passing result before usage can recommence.

- All test results must be recorded in a log or digital system alongside any corrective actions taken if issues are identified. This documentation is essential for quality control, audits, and regulatory compliance.

Conclusion

Bowie-Dick testing is a vital component to ensure the quality and safety of vacuum-type steam sterilisers, however, results should not be interpreted in isolation. By achieving passes on daily bowie dick tests, data is provided to corroborate efficient steam penetration. If you require more information on Bowie Dick testing or need further support with your autoclave validation, please do not hesitate to get in contact at [email protected] or use our contact form.

Further Reading

- BS EN ISO 285:2015

- BS EN ISO 17665:2024

- HTM 2010 Part 3

- Bowie J.H., Kelsey J.C., Thompson G.R., The Bowie and Dick autoclave tape test. Lancet. 1963, 281 (7281) pp. 586-587